Mechanical characteristics ※ The base adopts an A-shaped reinforcement structure to improve shock absorption effect, and the overall casting adopts a herringbone design to achieve high bending rigidity. ※ The structure adopts advanced mihanna material, which is tempered to eliminate internal stress and ensure optimal rigidity, precision, and durability The high rigidity structure originates from years of experience data accumulation and rational design of structural slenderness ratio, which improves the compressive and lateral bending resistance of castings High speed tool change structure design, combined with pre induction control and efficient cutting system, for tool change work. Actual test results show that the tool to tool exchange time is 1.8 seconds (60Hz), achieving high-speed tool change function.

15989519333 (Mr Xu)

Online consultation Message consultation

Main specifications and technical parameters

| Main technical parameters |

||||

| Mechanical specifications |

name |

Specifications |

Company |

|

| trip |

X-axis travel |

1100 |

mm |

|

| Travel Y-axis |

600 |

mm |

||

| Z-axis travel |

600 |

mm |

||

| Distance from spindle nose to worktable |

100-700 |

mm |

||

| Distance from spindle center to column slide surface |

690 |

mm |

||

| workbench |

Workbench size |

1200×600 |

mm |

|

| maximum load |

800 |

kg |

||

| T-shaped groove (number of grooves - size - spacing) |

5-18-100 |

mm |

||

| principal axis |

Spindle speed |

12000 |

rpm |

|

| Main spindle tool holder form |

BT-40 |

|||

| Spindle diameter |

Ø150 |

mm |

||

| Transmission mode |

Belt type |

|||

| Feed rate |

Fast moving speed X/Y/Z |

36 / 36/ 36 |

m/min |

|

| feed rate |

1~8000 |

mm/min |

||

| Machine accuracy |

X/Y/Z-axis positioning accuracy |

±0.005/300 |

mm |

|

| X/Y/Z axis repetition accuracy |

±0.003 |

mm |

||

| motor |

Spindle motor |

11 |

KW |

|

| X. Y and Z-axis drive motors |

2.0/2.0/3.5 |

KW |

||

| Oil pump |

DY-YBM-750 |

750W |

||

| Tool magazine |

Tool magazine capacity |

24 |

branch |

|

| Automatic tool change type |

Circular blade arm type |

|||

| Knife handle specifications |

BT-40 |

|||

| Knife handle pull nail |

45 |

degree |

||

| Maximum tool length |

300 |

mm |

||

| Maximum tool diameter |

Full of knives |

Ø80 |

mm |

|

| Neighboring empty knife |

Ø125 |

mm |

||

| Maximum tool weight |

8 |

kg |

||

| Tool change time |

1.8 |

sec |

||

| Land occupation space |

Mechanical height |

2900 |

mm |

|

| Floor space (length x width) |

3300*2800 |

mm |

||

| Mechanical weight |

5600 |

kg |

||

| Total electrical capacity |

20 |

KVA |

||

| Pressure demand |

0.5 ~ 0.8 |

MPa |

||

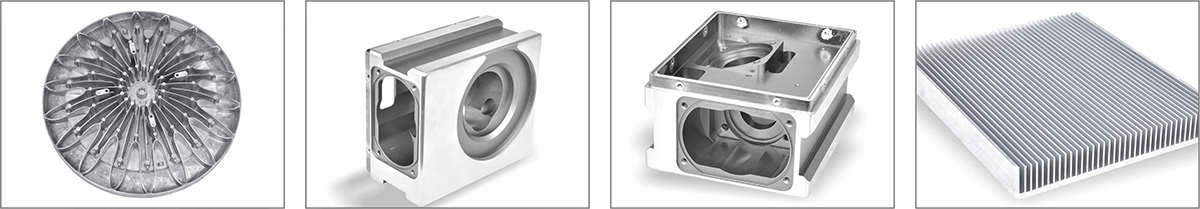

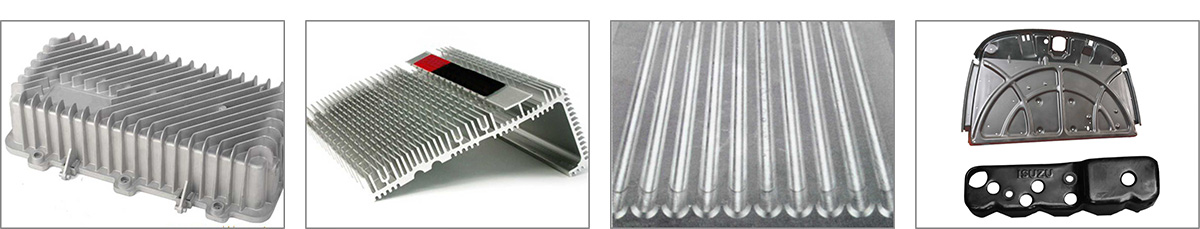

Processing applicationsProcessing application

Precision parts, 3C products, hardware, automotive parts, aviation, medical equipment

High rigidity main structureHigh rigidity major structure

The V series machine not only has the function of a good spindle, but also injects excellent ATC tool changing speed and fast displacement speed into the high-speed and efficient performance of the machine.

Specially designed for the processing of automotive parts and electronic consumer product parts, it is the best choice for production enterprises.

※ V6 V8、V10、V11、V12、V13、V15、 The three-axis adopts high-speed roller rail, which improves the characteristics of the machine while maintaining high speed and efficiency.